Liquid Support

Your liquid equipment was built to your specifications in terms of pump, row spacing, tips, and other options. Please have your serial number and Delivery & Inspection Sheet (from the back of your manual) on hand. Our staff will look up the original configuration of your equipment and help you.

Calibrating your sprayer is something that you will do immediately upon delivery of your new equipment and each year at start up. Calibration of Liquid Sprayers

Centrifugal Pump – How to adjust the output of a centrifugal

Centrifugal Pump for a Boomless Sprayer – Instructions for a boomless sprayer with a centrifugal pump

Diaphragm Pump Operation – Operation, Maintenance, & Troubleshooting

Diaphragm Pump Setting – How Set your Diaphragm Pump

Diaphragm Sprayer Operation with a SB-3 Control – How to operate a Newton Crouch diaphragm sprayer with a SB-3 control

Setting a Diaphragm Pump

A centrifugal pump is more often used with herbicides and can be dead headed. A diaphragm pump can create higher pressures and is often used to apply fungicides where a finer mist is desired. No matter which pump you choose, setting it correctly is essential to get the desired results. And proper maintenance is essential to the performance you deserve

Any time you use chemicals, measure and load your chemicals safely. The CleanLoad system is efficient, quick and easy to clean up. Hypro CleanLoad – View a video of the system that adds your chemicals, cleans your container and rinses your inductor.

Nitrogen Chart – Chart starting at 30 units per acre @ 19% increasing to 200 units per acre @32% is one of our most requested items

Newton Crouch developed a worksheet to help you determine your Orifice Selection – using water as a standard in gallons per acre

Click here to learn more about how to adjust the PTO on your Newton Crouch Equipment.

Please use caution as PTO adjustment can be dangerous. It is YOUR responsibility to use good safety practices. If you would like to learn more about good safety habits please click here or visit www.admausa.com

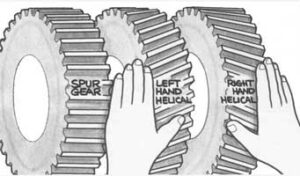

Facing the gear, first determine if the gear has straight or slanted edges. A slanted surface is a helical gear. A straight surface is a spur gear. Hold your hands up to the gear as shown in the diagram.

- The thumb on your left hand will point up following the slant on a Left Hand Helical Gear.

- The thumb on your right hand will point up following the slant on a Right Hand Helical Gear.

This is a very versatile sprayer. It was designed for budget-conscious municipalities to maximize their investment in a truck. Outlined below is a series of tutorial videos:

Safety First! Read, understand, and follow all safety precautions.

If you have a Newton Crouch Aluminum or Steel Skid. Please review these instructions. The skid sprayer parts are clearly labeled and explained. Skid Sprayer Operation

A mere 60 pages of technical information. You don’t need to read the whole thing, but if you “want facts, not opinions” this is where you get the answers. Nobody knows spraying better than TeeJet. TeeJet Technologies Tip Chart – TeeJet chart for various tip sizes, mph and spray patterns

Newton Crouch sells a lot of applicators with a John Blue pump because the pumps are real workhorses. Determining tip sizes on JBDW units

You can watch these 2 videos on John Blue applicators to see different options and some how to operate information.

This truck will do everything but crank itself and when setup correctly, you’ll be wowed by your results. However, it is complex and setting the valves correctly is your first step.

Below are videos on a wide variety of NC liquid equipment. The newest videos are at the bottom of the page. Your suggestions or requests are welcome.